Excavator augers are essential attachments used in construction, landscaping, and earthmoving projects. These powerful tools make drilling holes into the ground faster, easier, and more precise. Whether you’re installing fence posts, planting trees, or performing foundation work, an excavator auger can significantly improve efficiency and accuracy. In this guide, we’ll cover everything you need to know about excavator augers, including types, benefits, and maintenance tips.

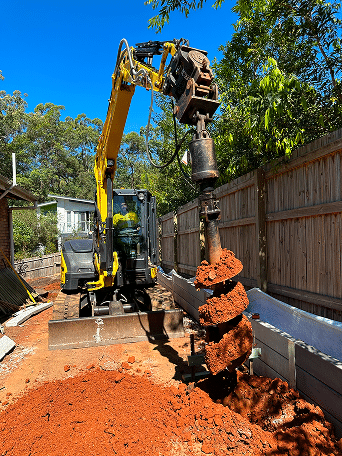

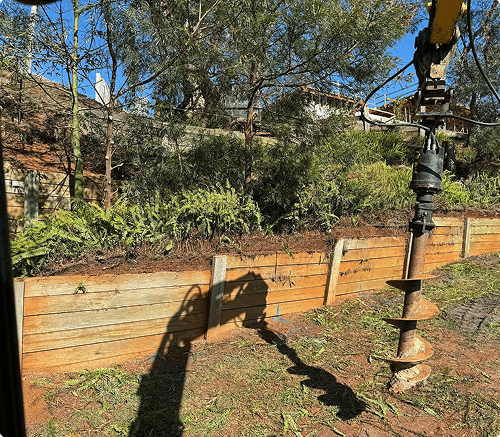

An excavator auger is a hydraulic attachment designed to drill holes into various types of soil and rock. It consists of a helical screw blade, also known as a flighting, that rotates to remove material from the hole. Augers are commonly used for tasks such as:

There are several types of excavator augers available, each designed for specific applications and ground conditions:

1. Standard Earth Augers – Ideal for digging in soft to medium soil conditions such as clay, loam, and sandy soil.

2. Rock Augers – Equipped with heavy-duty tungsten or carbide teeth to drill through hard soil, gravel, and rock.

3. Tree Augers – Specially designed with wider flights to create larger, cleaner holes for planting trees and shrubs.

4. Multi-Purpose Augers – Versatile augers that can handle a mix of soil conditions, making them suitable for various construction and landscaping projects.

Using an excavator auger offers numerous advantages, including:

Increased Efficiency – Drills holes quickly and accurately, reducing manual labor and project time.

Versatility – Can be used for multiple applications across different industries.

Precision – Produces clean, uniform holes, which is essential for structural integrity.

Cost-Effectiveness – Reduces the need for additional manual labor, cutting overall project costs.

When selecting an excavator auger, consider the following factors:

Soil Type – Match the auger type to the ground conditions for optimal performance.

Auger Size – Choose the appropriate diameter and length based on project requirements.

Excavator Compatibility – Ensure the auger attachment fits your machine’s hydraulic and mounting specifications.

Material Durability – Opt for high-quality steel and reinforced cutting edges for extended lifespan and durability.

To keep your excavator auger in top working condition, follow these maintenance tips:

Regular Cleaning – Remove dirt, debris, and hardened material after each use.

Inspect Wear Parts – Check teeth, flighting, and connections for wear and replace as needed.

Lubrication – Keep moving parts well-lubricated to ensure smooth operation.

Store Properly – Store the auger in a dry place to prevent rust and corrosion.

Excavator augers are invaluable tools that enhance productivity and precision in earthmoving and construction projects. Choosing the right auger, maintaining it properly, and understanding its applications can help you maximize its efficiency and longevity. Whether you’re a contractor, landscaper, or builder, investing in a quality excavator auger can make a significant difference in your work.

For high-quality excavator augers and expert advice, contact Ace Plant Hire today!

At Ace Plant Hire, our vision is to be the top provider of reliable, high-quality earthmoving services in Brisbane and South East Queensland, delivering exceptional results every time.

We Accept

Insured with